RTL-3301.480 Rittal LCP Plus - Liquid Cooling Package

Description:

Rittal LCP PLUS system

LCP Plus

LCP Plus

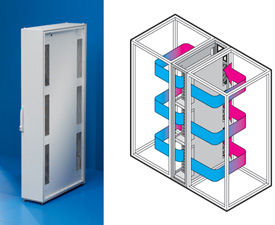

Using the same footprint and basic design as the Standard, the LCP Plus includes six fan modules that work in concert with the included heat exchanger to increase the useful cooling capacity to 95,540 BTU (28 kW). The LCP Plus is designed for cabinets 80” (2000 mm) high by 48” (1200 mm) deep and has a maximum air volume of 2825 cfm (4800 m3/hr). The LCP Plus (and LCP Standard) can be bayed to a single cabinet or between two enclosures. It is also possible to put a pair of LCPs on either side of especially hot cabinets for applications where extreme heat loads are present.

Liquid Cooling Package LCP & LCP+

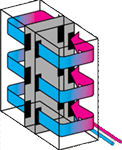

Developed to remove high levels of heat from server enclosures, the high density cooling solution from Rittal utilizes our new LCP air/water heat exchanger providing uniform, effective and affordable cooling for servers and IT equipment. The special horizontal airflow of the LCP represents an adaptation of this widespread cooling principle, providing cooled air uniformly throughout the complete height of the enclosure.

Cooling and heat removal, in the data center and at the enclosure level, have quickly become the most critical factors in data center design. Unmanaged heat removal may cause equipment damage or even failure, resulting in costly downtime. With the exponential increase in deployed servers, heat loads have almost quadrupled in the last seven years, leaving many facilities today unable to support such temperatures.

Safely bringing chilled liquids into the Data Center

Data center heat loads have increased dramatically as more components are squeezed tighter into densly packed rack space. Yet most mission critical servers are still being cooled using fans, air conditioners or a combination of the two. Frequent hot spots, rising cabinet temperatures and a patchwork of quick fixes are only band-aids that get around the obvious solution - high density cooling of the data center using chilled liquid.

Features:

Modular, upgradeable and temperature neutral cooling concept.

-Up to 20 kW (1410 cfm) cooling output, with three cooling modules possible per equipment rack

-Controlled variable speed fan and water flow based on actual heat load generated in cabinet

-Constant temperature - cold air provided at the front intake for optimized equipment use, hot air removed from rear

-Even air distribution along the entire height of the front 482.6 mm (19") mounting angles

-LCP bayed with one TS server rack and an option for a second TS server rack

-High energy efficiency in removing waste heat with no temperature impact in the room

~~~~

A modern approach with roots in the past-

Using chilled liquid in the data center is nothing new - water cooled mainframes were common into the 1990s - but the last decade has been dominated by fan and air conditioner solutions. As heat loads have risen the search for a better method for cooling the data center has led history to repeat itself with the use of chilled fluid systems.

Liquid cooling - super efficiency at your fingertips-

Liquids have a very high thermal capacity(around 3,500 times greater than air) which makes them ideal for removing heat from a data center cabinet. Convienently, many modern data centers already have a source of cooled liquid readily available. Rittal also offers a complete line of proven chiller products to circulate cold liquids if an on-site system is needed

The Rittal Liquid Cooling Package (LCP)air/water heat-

Piping chilled liquid through a Rittal LCP system protects your sensitive components by creating a carefully controlled cooling enviornment for maximum uptime. Much like an automobile radiator, a Rittal LCP system cools heated rack components with liquid cooled forced air. Rittal LCP systems are available in many configurations to tackle the exact heat load needs of your data center.

exchanger line - multiple options, cooler cabinets

No worries about liquid in the data center (no added heat either) and unit servicing is made simple- Rittal LCP systems and chillers use only spill-proof fittings and include built-in overflow trays for added peace of mind. The liquid and air routes are closed loop systems that do not add any additional heat into your data center enviornment. The LCP components are also hot swappable so you don’t have to take your critical data room servers down to service a unit.

Specification:

Proper Air Flow

Cold air provided at the front intake for optimized equipment use, hot air removed from rear

-RAL 7035 (light grey) textured paint

-RAL 7035 (light grey) textured paint

-Overall bayed dimensions - H = 2000 mm (80"), W = 900 mm (36") and D = 1000 mm (40")

-482.6 mm (19") full height mounting angles front and rear, 2000 lbs loading, depth adjustable

-Ten1/4 turn Velcro cable managers

-Set of PDS mounting brackets

-Air baffle to block air recirculation path outside 19" space between front 19" rails and TS frame

-LCP with three air/water heat exchanger cooling modules, 12-20 kW, up to 1410 cfm air throughput

-3/4" Quick coupling connectors for input and return from cold water

-3/8" Condensate drain hose

-LCP Controller ready for connection to optional SNMP CMC-TC for incorporation into network monitoring1)

-Includes captive nuts, screws and leveling feet

A full site accessment is recommended to give you the correct advice on system capabilities and the chiller requirements whether to your existing or planned new system.